CNC machineries revolutionize the production and design of complex components. From CNC Machines to CNC Mills, the realm of industrial automation has been reshaped and Australia stands at the forefront of this technological evolution.

CNC machineries are based on subtractive manufacturing. It works by eliminating materials, and not adding them, in order to turn raw materials into precision-crafted parts. The core of this technology is the CNC Machine, a marvel of technology that has become the cornerstone of manufacturing precision.

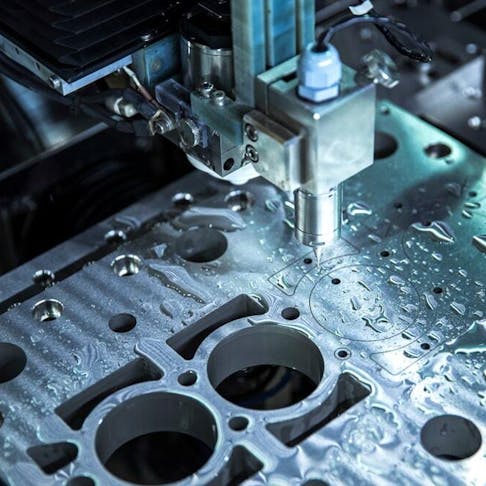

CNC Machines use digitalized computers to automate, monitor, and control movements in industrial machines. The digital program controls the machine’s high-speed cutting blades. It turns block of solid material into the precise shape you desire with the highest precision. This synergy is apparent in larger manufacturing installations. The seamless integration of CNC Machines with computers increases productivity and efficiency.

The mechanisms are intriguing and complex. CNC Mills work with solid blocks of material that are cut out intricate shapes using high-speed tools. The precision gained by this method is unmatched, making CNC machining the preferred method in industries where precision is essential.

Australia’s CNC Machine scene is thriving. Modern technology and a thriving industrial sector is creating new opportunities. CNC Machine Australia has a thriving technological landscape, with industries like aerospace electronic, automotive, and electronic that utilize CNC machining technology to increase precision and efficiency.

CNC Mills can play a critical role in shaping the manufacturing industry of tomorrow. These machines can create exact parts in a variety of industries by using computerized codes. CNC Mills, with their efficiency and precision, are essential instruments for experienced engineers.

CNC machined parts offer many benefits that go beyond the limits of conventional manufacturing. One of the key advantages lies in the ability to produce extremely intricate and complex components with consistent precision. The digitalized nature of CNC machines also permits rapid prototyping, which reduces the time and cost that are associated conventional manufacturing methods.

CNC Machine Tools, a component integral of this technological eco-system, are also important in enhancing the efficiency of CNC Machining. These tools include a wide variety of tools that are used to aid the process of machining. They are used to cut, shape and drilling, or for finishing. The synergy between CNC Machines and CNC Machine Tools ensures a seamless workflow, maximizing precision and minimizing waste.

CNC machining has been adopted by industries across the board because of its revolutionary capabilities. In aerospace, CNC machining plays a pivotal role in crafting complex components that require the highest level of precision and reliability. CNC machine’s effectiveness is advantageous for the energy sector, which produces complex components for machines as well as other infrastructure.

CNC machining has also proven its capabilities in the automotive and electronics industries. CNC Machines’ capabilities are equal to the complex electronic devices or the precision required to design and build automotive components. From constructing components for engines to shaping complex electronic circuits CNC machining proves its worth in a variety of applications.

CNC Machining is revolutionizing the way we work in manufacturing. CNC Machines are the basis of this revolutionary technology. CNC Mills and CNC Machine Tools are the three pillars. CNC machineries, with their accuracy, efficiency, precision, and adaptability, will continue to be a major influence on the future of manufacturing Australia, as well as across the world.